Muskegon Lake Nature Preserve: Habitat Restoration

This project involved the restoration of a natural public area. The nature preserve was polluted from foundry sands and metal contamination, in addition to being heavily overgrown with invasive species.

The Muskegon Lake Nature Preserve located on Lake Avenue just west of the causeway is a targeted area of concern (AOC) that is to be addressed during the proposed work in the area. The area had been filled in the past with foundry sands showing elevated levels of various metals. Miscellaneous concrete debris was present, detracting from the aesthetics of the preserve. In addition, invasive species had infiltrated the area and had dominated natural species. The desired goals of this project were to improve the general habitat of the nature preserve, increase biological diversity and vitality in the area and improve the overall beauty and appeal of the preserve.

To accomplish this, several activities were completed. Wetland areas were enhanced by removing soil and lowering the elevation of targeted areas. New disconnected wetlands were generated where amphibious species can flourish without predation by fish. In other areas, hydraulic connections were created to restore natural water migration within the preserve. Intense invasive species control were implemented in an attempt to restore native species and natural diversity.

The entire goal of this project was to improve the preserve habitat and return the area to a more natural setting allowing environmental conditions and wildlife diversity to rebound. When finished, the area was restored to a clean, natural environment for residents and local wildlife to enjoy for years to come.

UPDATE - Muskegon Lake has officially been removed from the EPA’s list of most polluted sites. Read More Here!

City of Ann Arbor Sewer Televising and Cleaning

The City of Ann Arbor maintains in excess of 370 miles of Sanitary and 293 miles of Storm Sewers within their jurisdiction. The City has contracted with Taplin to support the CMOM (Capacity, Management, Operations and Maintenance) objectives for their sewer infrastructure.

Taplin is responsible for performing the condition assessment of the City’s sewers ranging in size from 8”-42” utilizing CCTV equipment in accordance with NASSCO PACP Standards. The inspection crews will complete the video inspection of approximately 3 million feet of sewer over a three year period. In support of the inspection efforts, Taplin will perform cleaning of various sewers to remove debris inhibiting camera progress.

In addition to conventional CCTV technology, some of the City’s sewers will require Sonar and Multi-Sensor Technology to provide condition assessments to the City. Taplin Group owns technology and self-performs these services with our modern fleet of inspection equipment.

All inspection video and PACP Condition Reports are submitted to the City through Taplin’s FTP site to streamline data exchange efforts.

Exclusive Hazardous Waste Transportation Provider

Taplin is part of a collaborative team responsible for the loading, transportation and disposal of hazardous waste from a local pharmaceutical production facility. Taplin is the exclusive transportation provider of the hazardous waste collected. Hazardous material used in the manufacturing process passes through a reclamation process before transport. Hazardous material that is not reclaimed back into the manufacturing process is then sent to holding tanks. From the holding tanks, it is transported as hazardous waste to cement plants where it is then used as an alternative fuel. The holding tank area consists of 4 above ground tanks with a capacity of 155,000 gallons. Tank level capacity is critical to production. If the tanks reach a level of 155,000 gallons, then production will shut down.

On an average day Taplin takes 5 loads a day from the plant to one of three cement plants which are located in Paulding, Ohio; Logansport, Indiana; and Greencastle, Indiana. Cement plants use the hazardous waste as a fuel for their cement kilns in the creation of cement. On days of high production when the tanks near a critical limit of 155,000 gallons, Taplin hauls as many as 8-10 loads a day.

In 2020 Taplin hauled 1,469 loads and over 8 million gallons of hazardous waste from the pharmaceutical production plant to the cement plants. Since 2016, Taplin has played a critical role ensuring uninterrupted production at the plant through exceptional service of hazardous waste transportation

Abatement, Demolition and Contaminated Soil Removal

This project involved the demolition and remediation of a former manufacturing site under a Michigan Analysis of Brownfield Cleanup Alternatives Cleanup Plan. The project involved three major phases that included asbestos abatement, demolition, and the excavation of contaminated soil. Taplin assigned a crew of 9 who were all 40-hour HAZWOPER trained including some with additional asbestos abatement certifications.

Tasks involved the abatement and disposal of asbestos-containing materials, the removal and disposal of asphalt & concrete materials, the removal of three above ground storage tanks, demolition of a 20,000 square foot building, excavation and disposal of 55,000 tons of petroleum-impacted soil, the abandonment of several monitoring wells and deep aquifer source and storm sewer removal and replacement.

Taplin coordinated with multiple agencies during the project including the MDEQ, MDNR and the City of Bloomingdale. Excavation extended into the Kal-Haven bike trail and the new sewer outfall extended across the trail. Taplin minimized shut downs of the trail and coordinated around several special events associated with the trail and the city. The project was completed in 7 months, on time and on budget with no incidents.

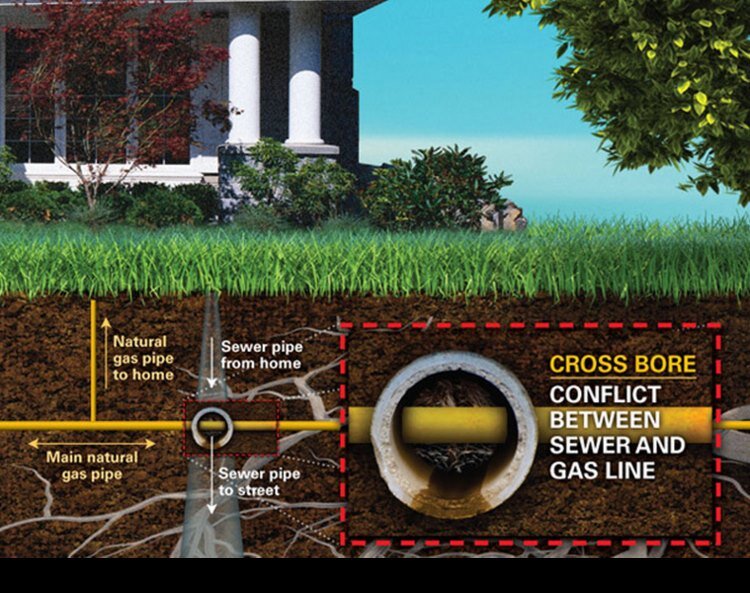

Sewer Locating/Cross Bore Prevention

Since 2013, the Taplin Companies have been providing locating services to one of the largest gas providers in the State of Michigan. The contract involved the use of robotic cameras that would travel down sewer mains and launch an auxiliary camera from the main into the sanitary service lateral coming from a residence or building. The auxiliary camera is equipped with a sonde that transmits a signal that is received above ground by a technician. The technician follows the signal to trace the path of the sewer lateral and confirm depth to surface. This information is then captured on a diagram and used by directional drilling operators to assist them in horizontally drilling new gas line services

Project Objectives:

*Provide accurate location and depth of sanitary sewer laterals to support a gas utility’s efforts to update gas mains in communities.

*Prevent cross bores to sanitary sewer laterals and avoid catastrophic accidents."

Main Interceptor Cleaning Huntington, WV

Taplin utilized one of our large diameter cleaning units capable of producing 200 gallons per minute at 2500 PSI operating pressure to deliver flow to the cleaning equipment. Taplin had to run 1 ½” high pressure hose in excess of 3,500 lineal feet through an easement to reach the remote reel stationed at each manhole. The remote reel was transported and powered by a John Deere Skid Steer. Even with the remote equipment, some of the manholes within our scope of work could not be accessed through the utility easement. This being said, Taplin provided reels capable of cleaning in excess of 2,500 lineal feet from one location.

The capacity of the sewer prior to cleaning was reduced by 40-60% due to the volume of debris. As the manholes are not accessible with conventional vacuum equipment, Taplin utilized hydraulic pump equipment to remove the debris from the sewer. This equipment has a smaller footprint and is able to be maneuvered through the easement with off road construction equipment that Taplin pulled from our Remediation Division for this project. Prior to mobilization, Taplin’s Fleet Maintenance Division fabricated two debris separation containers for this project. These containers (like the easement reels) could be pulled through the easement with construction equipment so they could be placed adjacent to each manhole where extraction was taking place. During the cleaning operation, the debris would be pumped from the sewer with the hydraulic dredge pump into the de-bris separation tank. The tank was specifically designed to allow enough surface area for the debris to settle out before another pump transferred the effluent back to the same manhole. Taplin utilized a PC-138 excavator to transfer the grit from the separation tank to a drying box where the material was allowed to dewater further before being transported into open top roll off boxes. This process allowed a continuous cleaning operation negating the need to shut down to dump.

Taplin provided an off-road CCTV/Sonar inspection unit to perform the inspection of each section once the cleaning was completed. Taplin has been able to restore each completed section to 100% hydraulic capacity.

Contaminated Soil Excavation & Disposal

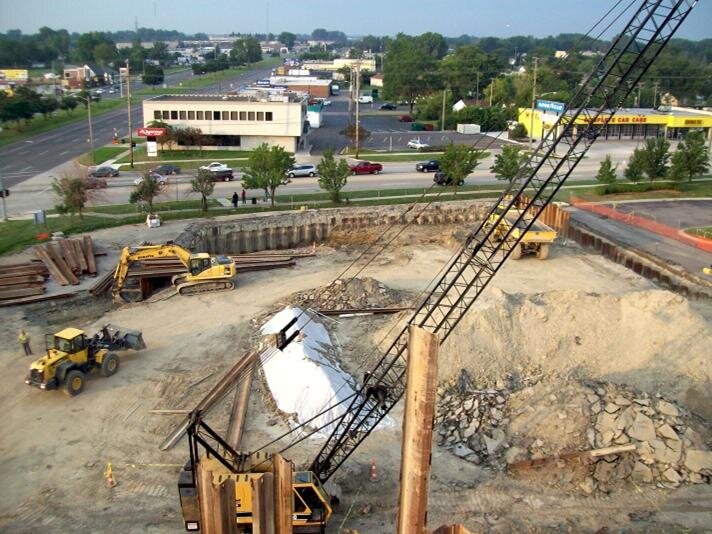

Taplin was contracted by the Michigan Department of Natural Resources and Environment (DNRE) to excavate and dispose of gasoline-contaminated soil from a former auto center in Clinton Township, Michigan. The project required removal of several feet of overburden, and then installation of sheet piling walls to allow deep excavation and removal of contaminated soil.

Using a PC-300, the crew began by digging a five-foot deep trench around the perimeter of the project footprint in preparation for the installation of the sheet pile wall. The clean overburden was transported and stockpiled to an area located near the middle of the project footprint. Approximately 1,000 feet of sheet piling was installed by a sheeting subcontractor 34 feet below the trench floor and flush with the bottom of the trench. The piling was bolstered with additional support in the form of anchors and bracing installed at 25-foot intervals. The anchors consisted of a single sheet pile section driven 30 feet into the bottom of the excavation while the bracing involved a support beam installed between the sheet pile wall and the anchor. Crews then built a trench crossing to provide truck access.

Crews then installed a well-point dewatering system to control groundwater within the sheeted area. The crew began excavation of the impacted soil beginning at the northwest corner of the footprint. To ensure the stability of the sheet as the soil was removed, Taplin designed a special leapfrogging approach that also helped to make the excavation process more efficient. Taplin worked in 50-foot sections, first taking out 12 feet of overburden and stock piling to get at the contaminated soil below. The contaminated soil was then excavated to a depth of about 26 feet and then backfilled immediately using the stockpiled overburden. Since the soil was impacted with gasoline, Taplin utilized a vapor suppressant foam to minimize the risk of fire.More than 23,000 tons of contaminated soil were removed and transported to a designated landfill in Lenox, Michigan. The project lasted 15 weeks and was completed within budgetary parameters.